A single house that contains infinities

Combining revolutionary design and public access into one uniquely ambitious project, DUS architects are creating the world’s first 3D printed, full-size canal house in Amsterdam.

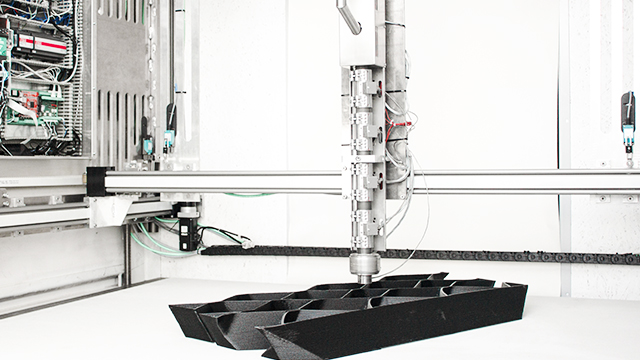

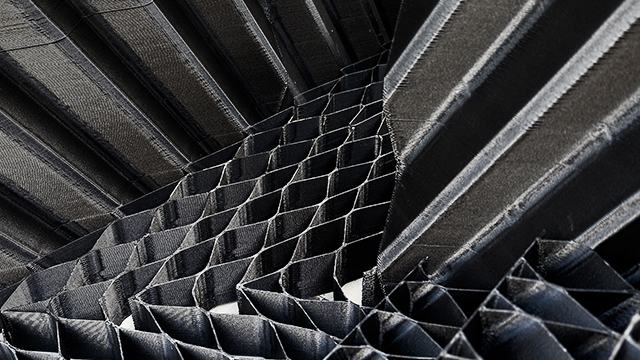

For DUS, this project investigating XL 3D printing and showcasing different materials, shapes, and structures represents not just an architectural feat but also an opportunity to revolutionize the building industry. As a catalyst for cross-discipline innovation, the project pushes the boundaries on parametric design, bio-based building materials, smart technologies, and customizable construction methods and techniques. The goal: to offer new tailor-made housing solutions worldwide.

Designed as an open exhibition, the canal house provides the DUS team and its international partners with a live feedback loop, accelerating the design and research process. As an architectural test case, the canal house is the ultimate embodiment of DUS’s No. 1 principle: design by doing.

Printing the size of their ambitions

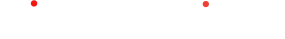

To 3D print its own canal house, DUS also had to create its own 3D printer. They have now developed two gigantic on-site printers capable of 3D printing elements as large as 2 x 2 x 4.5 meters. Developing advanced 3D modeling software and 3D printing technologies – and designing the structural elements of the house – takes enormous computing power. Just like the kind DUS architects find in their ThinkStation P710 and ThinkPad mobile workstations.

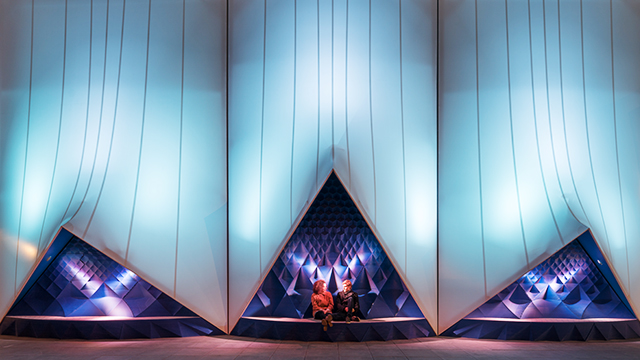

“Architecture that confronts each person’s imagination creates opportunities for communication between the private and public domain, and between individuals.”

Check out what's in the hands of DUS designers: ThinkPad P50 and ThinkStation P710

Latest Blog Updates

3D Printed Urban Cabin Opens in Amsterdam DUS architects built an entirely 3D printed mini-retreat, to escape the speed of everyday city life. The 3D printed Urban Cabin transforms a former industrial area in Amsterdam from a vast empty space into an urban retreat, complete with pocket …