Making a difference is within our grasp

Each year approximately 1,500 children in the US alone are born with upper-limb differences. Many of these children are unable to use traditional prosthetic devices. For those who can, the high cost may put them out of reach.

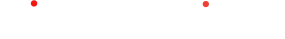

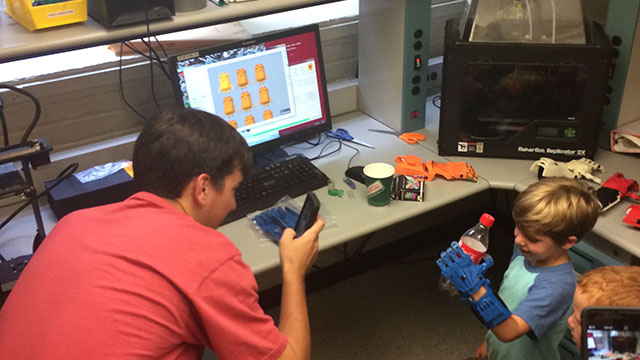

In the fall of 2014, biomedical engineering students at the University of North Carolina at Chapel Hill created a prosthetic device for a child who had few options. Using 3D printing, they were able to make this hand for less than $40 worth of materials. While going through this process, these students realized the growing need to make hands for other children, and The Helping Hand Project was formed.

Using a mix of open-source and custom designs, The HHP continues to provide prosthetic devices to children in need. The HHP maintains contact with these children, so they may receive new devices as they age. And through in-person meetings and online groups, The HHP helps these kids and their families with support that goes beyond providing a prosthetic device.

All hands on deck

Many children who have physical disabilities and need prosthetic hands can use standard designs, but some require custom designs that fit their unique anatomies. For all kinds of hands, The HHP engineers design and print devices using SOLIDWORKS applications on the ThinkStation P500. And to keep the waiting list for new prosthetics as short as possible, The HHP counts on Lenovo’s lead ThinkStation engineer to quickly 3D print devices at Lenovo’s own facility.

“Thanks so much to The Helping Hand Project for helping my son feel like a super hero.” – Wendy Barnes, whose child received a HHP device

Latest Blog Updates

A New Design for a New Hope If a new bicycle or video game system can elicit shouts of joy on Christmas morning, imagine the excitement and hope expressed by Amy, a girl in Texas who received a new prosthetic arm. As an early Christmas gift in …

12 months. 12 lives changed forever. Since The Helping Hand Project began as a student-led venture at the University of North Carolina at Chapel Hill, demand for its 3D-printed hands has outstripped supply. Outdated technology, including older model 3D printers, had slowed the delivery of prosthetic …